Navicom | Habour Pilot lightweight

BACKGROUND

Far from shore a helicopter drops a marine pilot to the deck of a ship preparing to dock alongside an oil rig. He is carrying a Navicom Portable Piloting Unit (PPU) to provide the precise information needed to dock a large ship in a small space anywhere in the ocean. Accuracy is critical as what can be a simple exercise in a port, becomes a life or death situation in the open sea. Navicom’s PPU utilises a combination of satellite and land-based data to provide accuracy between 20cm and 50cm, depending upon the sophistication of the unit used.

THE ISSUES

Navicom needed to package its highly portable units to reflect the product’s improved technical capability and enhance its usability. The PPUS’s application raised some unique issues for the Procreate team:

The solution needed to be compact and lightweight in order to be carried in a backpack with a laptop by the pilot being lowered and retrieved by helicopter

It needed to be robust and absolutely waterproof to withstand accidentally being dropped on a deck or ‘washed’ by a wave

The PPU and its operating antenna needed to be easy to install and operate in extreme sea and weather conditions

It is a low-volume product so the design needed to take into account how the product would be manufactured and assembled; it needed to sit comfortably alongside competing brands that could be manufactured at a lower unit cost

It was also a high-value unit that had to reflect the asthetics of previous Navicom products and those of its higher-budget competitors – as well as being built with the expectation of a long operational life.

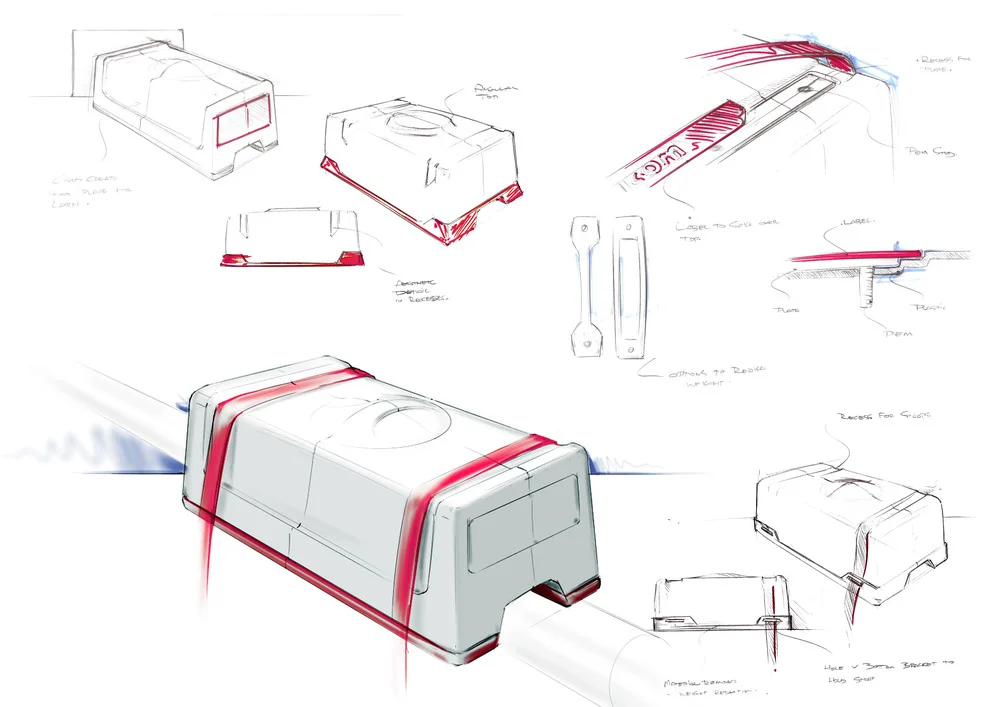

THE SOLUTION

Procreate is justifiably proud of the design it developed for the Navicom HP and Aerial Mount. The first step was to remove material from the main internal chassis to reduce the overall product weight, while still maintaining the integrity of the shielding that those components provided to the electronics. The use of an internal aluminium chassis transferred the internal stresses generated by the sealing interfaces and minimises the strain within the plastic screw bosses. This approach successfully contributed to reducing the overall weight of the unit by 20%.

The Navicom HPL unit itself was fitted with a powerful magnet that aggressively attached it to the rail or deck of the ship. The accompanying antenna is designed to operate at a distance from the unit and needs to be attached to the ship rail. Previously the fitting only accommodated a square rail and an adaptor had to be deployed if the vessel had a different shaped railing. Procreate solved this by developing a clamping system that was just as effective on round or square-shaped rails and could accommodate a wide range of different rail shapes and sizes.

A lift in the product aesthetics was achieved by using injected moulded components as opposed to fabricated components. This enabled a much more refined form to be used and also accommodated the current low-volume production runs with the ability to scale should demand grow. The decision was made to provide openings in the injection moulding for LED indicators and connectors, post processing. This minimised the tooling and production costs while providing the greatest flexibility for future design variations. Engineering plastics were also used for their lightweight, high-strength properties as well as their resistance to environmental degradation.

Sustainability was also considered as part of the product-life assessment. The product components are designed to be reused as opposed to recycled so that the end-of-life for the various components can extend well beyond that of the initial product. Removing spent batteries, magnets and electronics has also been simplified to ensure their environmentally appropriate disposal.