Specification

We translate product goals into clear, practical engineering specifications that guide development from concept through to production. This includes defining materials, functional performance, environmental conditions, and manufacturing considerations to ensure designs meet performance targets while being optimised for appropriate manufacturing processes.

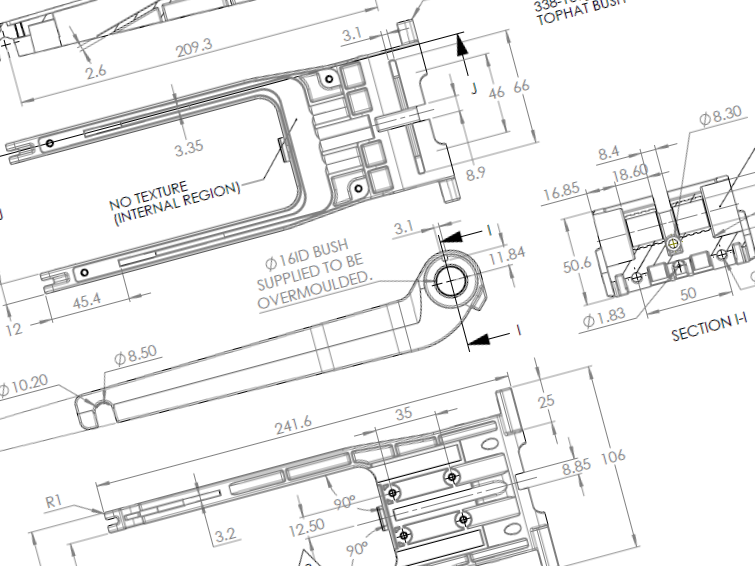

Design and CAD Modelling

We turn design requirements into precise digital models that allow ideas to be explored, refined, and validated early. Our 3D CAD work is developed with manufacturing in mind and supported by clear documentation, enabling confident decision-making and smooth collaboration with suppliers.

Analysis

Analysis is used to reduce risk and increase confidence before committing to tooling or production. We apply FEA (Finite Element Analysis) , tolerance stack-up assessment, DFMEA (Design Failure Mode and Effects Analysis), and targeted testing of physical prototypes to verify performance, identify potential issues early and support informed design optimization.

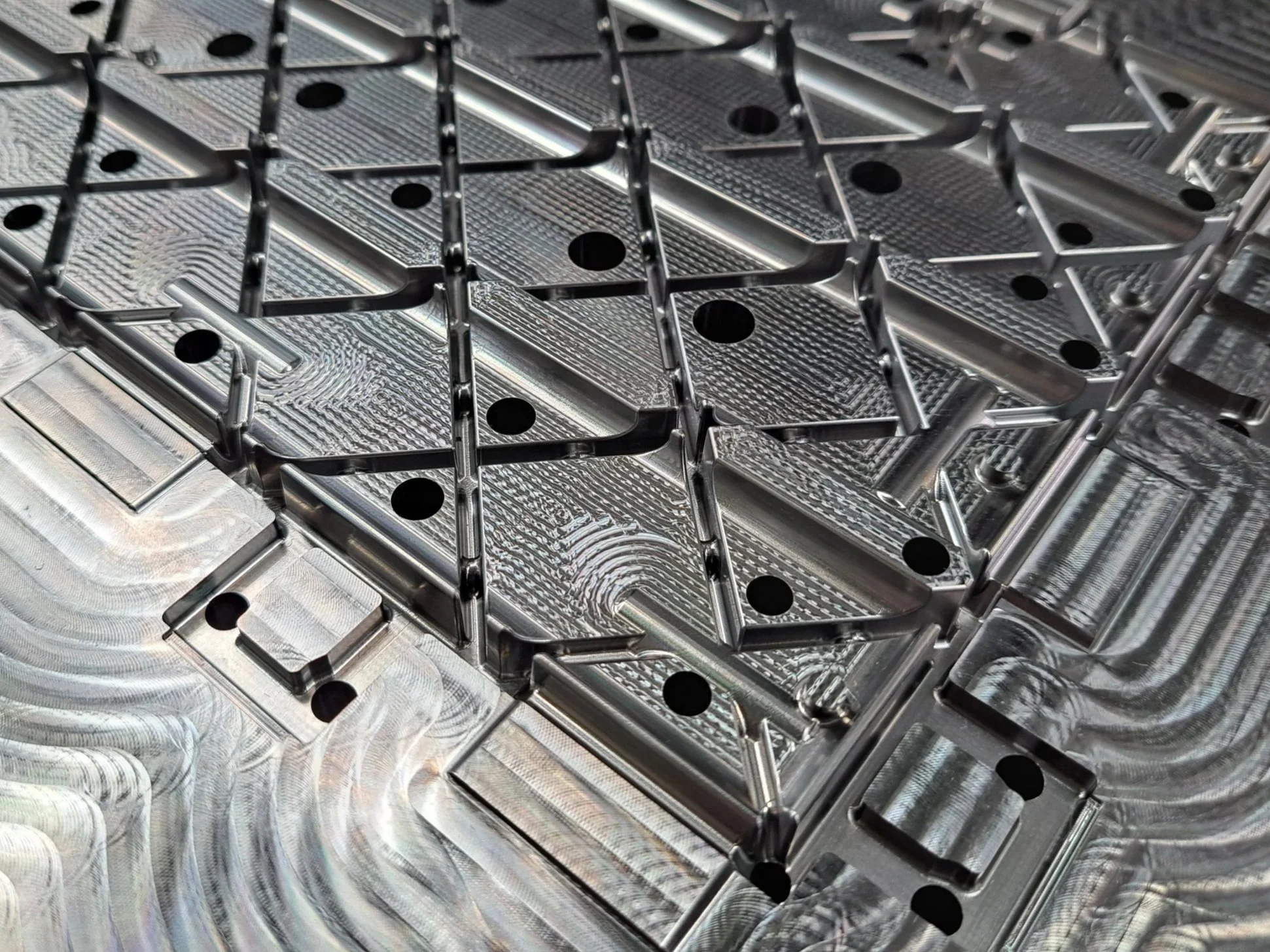

DFM

Design for Manufacture is embedded throughout the design process to ensure products are efficient to produce and cost-effective at scale. We optimise geometry, tolerances, and materials to suit selected manufacturing processes while maintaining performance and quality.

Manufacturing Support

We support clients through production approval and validation, part sign-off, and quality assessment. By working closely with manufacturing partners, we help ensure a smooth transition from design to production and consistent, reliable outcomes.