From a Great Idea to a Finished Product

Every great product starts as a great idea. However, there are always far more great ideas than there are great products. We work with you to assess the potential of your idea and to transfer it from being a concept into a reality. This can start over a coffee and continues through a journey that will ultimately see your product designed on paper and as a 3D computer model.

While our discipline is design, we are also businessmen. Making sure that your design is commercially viable is part of the assessment process. This includes meeting international best practice and working with you to ensure you maximise your return from the development investment.

The Product Design Process

There are two main disciplines involved in the product design phase of a new product development project:

Industrial Design – an ‘outside-in’ approach that combines the knowledge of ergonomics and usability with artistic skill to create attractive, user-friendly, innovative products.

Mechanical Engineering – an ‘inside-out’ approach that is focused primarily on how the product functions.

To achieve truly great product design, these two disciplines must be in balance. At Procreate, we benefit from having both disciplines under the same roof. It allows us to focus on delivering excellence across the board to ensure the products we design fulfil every aspect of the design specification and can be manufactured efficiently and reliably.

This is a consultative process and the development of prototypes at relevant stages of the project gives our clients the ability to take a hands-on approach to considering the options available to them in terms of how the product looks, functions and will be manufactured.

Once a concept has been finalised Procreate also has the expertise to drive the tooling process which ensures that the design you have signed off on is what you will receive off the production line. This has also led to Procreate having a greater involvement in the manufacturing process than most design houses. You can have confidence in our ability to deliver on what we design in the most cost-effective and environmentally efficient means possible.

Industrial Design

Industrial design focuses on the interfaces between a product and its users - these may be physical or visible - and how they affect the user's interaction with the product.

Industrial design is concerned with the product aesthetic and usability and addresses the market that the product is targeting through appropriate application of form and function.

The aim of industrial design is to ensure the product delivers the maximum benefit to its users - at a functional level as well as at aesthetic and subconscious levels.

Good industrial design will ensure that a product stands out from competitors, is a pleasure to use and aligns with a company's brand. It can add considerable value to that product, which is often realised in increased market share, greater profitability or lower cost-of-sale.

INNOVATION / IDEATION

Whatever term you use for it – innovation, ideation, visioneering – a source of great new product ideas is a critical foundation for building a successful new product development (NPD) culture in your organisation.

The Procreate team can help you establish an internal process for the creation and capture of new product ideas, and in establishing robust criteria for assessing which new product ideas should qualify for further investigation and R&D investment.

This ensures you capture and explore every great idea as and when they occur. It means that your entire team understands the information you need to capture to make a considered assessment and that it will seamlessly dovetail into the development process.

Design Research

Design research is concerned with the processes or technology the design may require in order to satisfy the customers' needs.

Your research may focus on:

new technologies that could be beneficial in the product development

understanding and quantifying the market for a proposed new product or products

examine similar products to those being designed

work to understand how a specific design challenge may have been solved previously

how to improve the design this time around.

Whatever your research requirements, the Procreate team can help you.

We use design research tools to provide useful information that can add depth to any product development. Whether it is researching a potential product market, technology or history, design research enables us and our clients to fully understand, verify and leverage this knowledge throughout the design project.

Design Specification

The design specification is a detailed plan of the requirements for a product's design. Focusing on the function of the product, it addresses questions such as:

What is the purpose of the design?

Form and aesthetics - how will the product look and feel? What style will it have?

What functional characteristics must the product have?

What are the user requirements for the product – what does the person using your product need to get from it?

What is the scale of production – is the product mass produced, batch produced or done as a one-off?

What is the budget and what restrictions might that impose?

What is the timeframe and available resources?

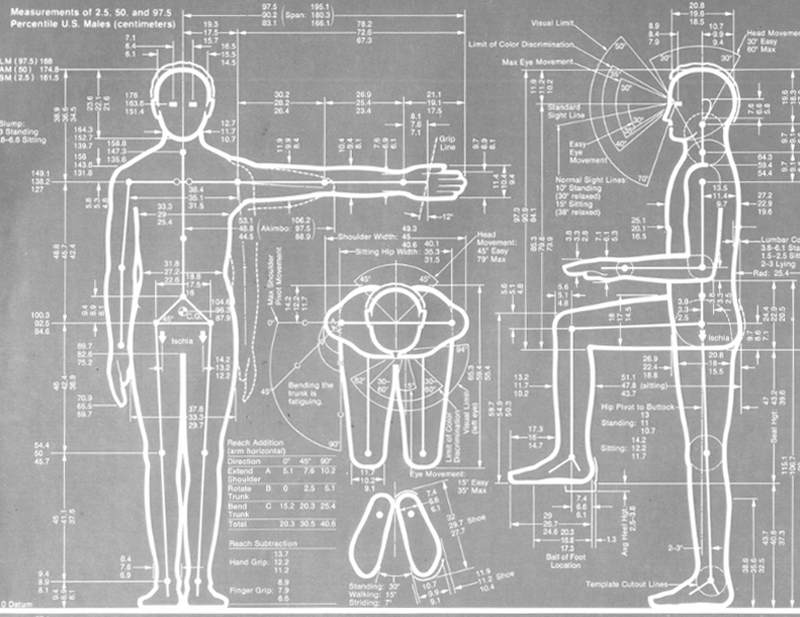

Usability Design / Ergonomics

User interface design and ergonomics is concerned with ensuring that a product is simple, easy, natural, and safe to use. It addresses all aspects of the product's design including its weight, size and feel and how the product will interact with the human body.

Rigorous study of human beings in environments of interest provides the designer with an understanding of what issues the user may currently face and/or what issues have been or can be resolved through the product design process. Techniques such as using anthropometric data (human sizes) and ethnographic research (interview and observation with prototypes) help us to achieve this.

Today many products are differentiated through the development of the user interface and ergonomics alone; the simplicity of a new MP3 player or the innovation of a new chair designed to reduce the likelihood of RSI are good examples.

Procreate strongly believes that elegant, user-focused design is a major factor in delivering a product’s competitive advantage, particularly in today’s increasingly cluttered market. We are experienced in developing user interfaces for a broad range of applications and we consistently apply the best international practice in ergonomics, usability and user-interface design in all that we do.

Aesthetic Application

Differentiate your products and strengthen your brand

"Between two products equal in price, function and quality, the one with the most attractive exterior will win" Raymond Lowey

Procreate ensures the visual elements of a product are treated in a sophisticated and balanced way. Through a considered application of aesthetics, value can be added to a product without increasing its cost. This is a very effective way of differentiating a product in the market and has a direct impact on the market’s perception of your product and its price point.

The significance of a strong brand is becoming more important in current saturated markets. By mapping out the core characteristics (visual elements, qualities or experience) of a company’s brand and applying these throughout their products, we are ensuring that the product and the brand are essentially integrated. This can facilitate brand recognition for a company, not just through a two-dimensional logo, but through the three-dimensional elements of a product.

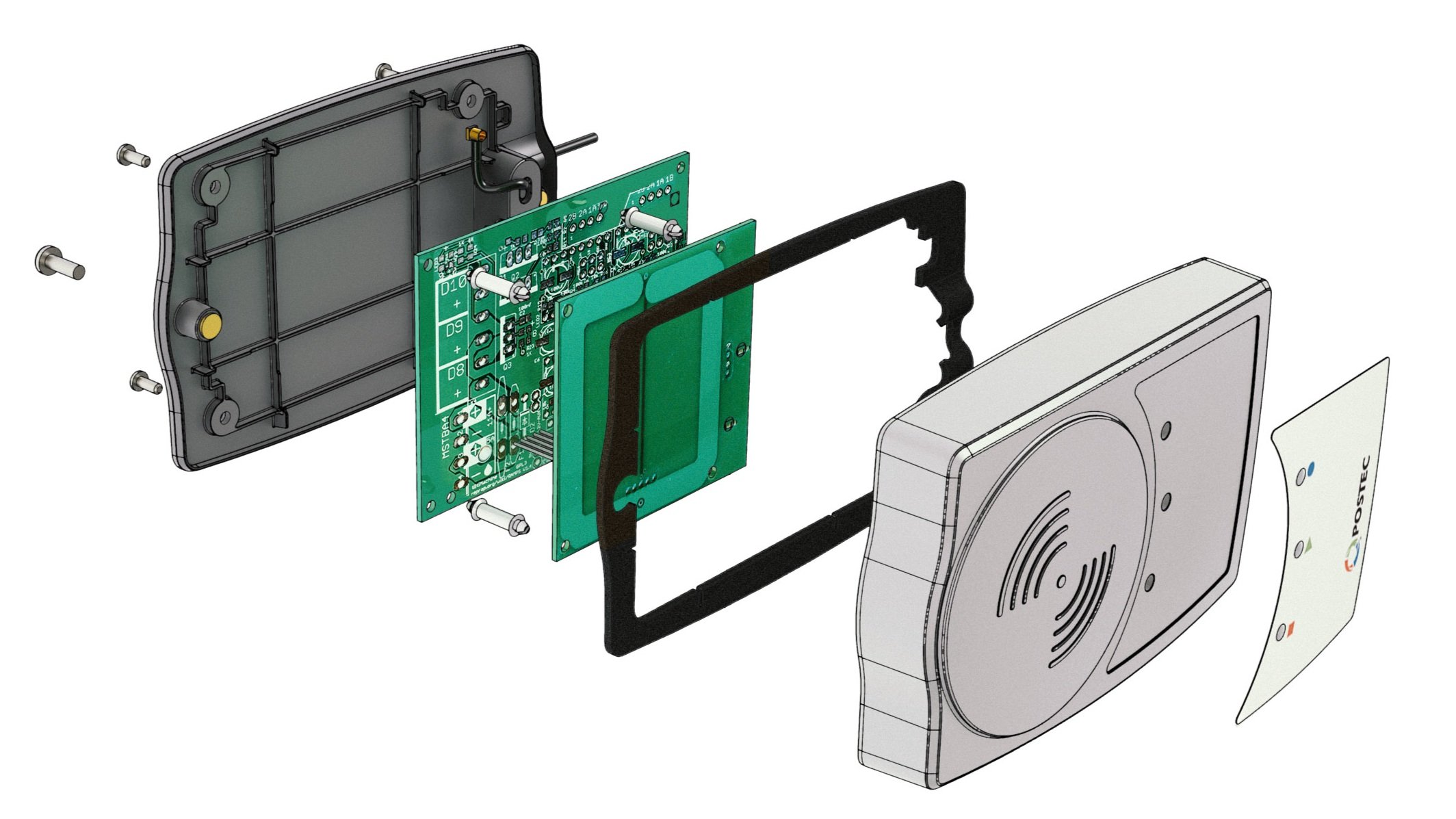

CAD Modelling

The Procreate team works extensively with 3D CAD Model generation in Solid Works. This enables us to achieve a whole range of product design processes within a digital environment. CAD modelling enables us to thoroughly investigate design alternatives, including applying a range of tests and analysis whilst still working in an electronic form.

CAD modelling enables us to validate the various concepts and render them in a form that can be used by our clients to gauge initial response to the design. We can apply complex 3D surfacing to CAD models to provide an accurate representation of the aesthetics of a product. More photorealistic models can also be used in marketing material prior to the product's manufacture.

Mechanical Engineering

Mechanical engineering focuses on the functionality of a product – what it needs to do - and ensures that it is both reliable and sustainable.

Mechanical engineers will be involved in material and component selection to support the product design and any regulatory considerations. There are very few products designed today that don’t require some aspect of mechanical engineering. It is concerned not only with the functionality of the product but also in making it more efficient to assemble and ensuring its ‘end of life’ is as environmentally friendly as possible.

Virtual testing

We can use CAD models to virtually assess the effects of stress on the product and how various environmental factors (e.g. weather, salt air) might impact on it. This gives you much greater certainty of the robustness and general reliability of your product prior to manufacture.

Mechanical Engineering

Mechanical Engineering focuses on the physical components that make up a product. The shape of components, the selection of appropriate materials and the use of appropriate manufacturing and assembly methods are critical to profitability and can spell the difference between a highly profitable product and a failure.

Many factors are key to good mechanical design including intended production volumes, environmental factors, applied loads, the speed of movement, cost and statutory regulations. All of these need to be considered in order to produce a design that is optimal.

Testing and verification of components and assembled products minimises the risk of product failure or recall. A good mechanical design will reliably deliver the functionality demanded of a product at the lowest overall cost.

Mechanical Analysis

A subset of testing is mechanical analysis. This is an output of the CAD model that enables us to break down a product into its component parts and then reproduce the effect of applying different loads to those parts in a realistic computer environment. It enables us to performance test various componentry to see which ones will deform or break, including testing in extremely hot or cold environments.

By verifying whether the design is robust at this very early stage, you may save considerably on prototypes and further testing. Mechanical analysis can also be used to assess if the material selected is correct and help us to understand what would happen if different materials were used. This enables us to explore more sustainable and environmentally friendly alternatives.

The benefits of Procreate's side-by-side design

Once again the inherent benefits of Procreate being able to run both the aesthetic and mechanical design side-by-side ensures that the entire design process is able to respond very quickly to any changes that result from the testing and analysis.

PHOTOREALISTIC PRODUCT RENDERING & ANIMATION

Selling your product before it’s manufactured

Many of our clients need to have some kind of product collateral prior to the product going into production. Sometimes it is simply to validate the look and feel of the design with various stakeholders, but more often than not it is to make a presentation to potential investors, distributors, resellers or customers.

At Procreate we can create photorealistic images and animations of the product we have created in our 3D software. This simulates the materials to be used and the colours and creates realistic lighting environments that deliver a persuasive representation of the final product. Convincing two-dimensional renderings can also be achieved using advanced software at the earliest stage of product development.

Model Making & Prototyping

The purpose of a good prototype is to provide a functional, lifelike depiction of the product that can be used to test aspects of the product's design during the design process. Prototyping techniques vary depending upon both the product being designed, and the stage of the design process that the prototype is being used for.

We are experienced in producing prototypes using a wide variety of materials and techniques such as SLA (stereolithography), CNC machining and foam models; we work with a variety of specialist sub-contractors to highly customised prototypes where required. Prototypes can provide an invaluable tool to help refine a product's user-interface, aesthetic or other attributes. This can occur at almost any stage of the design process – from examining a range of different concepts to testing functionality and assessing how you might finally manufacture the end product.

Not all our designs are prototyped but it is something we strongly recommend, particularly if there is a relatively high cost of manufacture. While we can make a lot of assessments using 2D and 3D modelling, nothing beats the hands-on assessment of a product's function and form that you get from physically touching it.

Money spent in prototyping is often ultimately saved by making the design even more cost-effective to manufacture going forward. It can also be critical to secure investor funding as a physical form is far more finance-friendly than just a great idea.

3d printing

Procreate has a range of 3D printers in-house that allow the team to quickly create physical test pieces without the added time and cost of working with external suppliers. 3D printed parts are extremely helpful for verifying fit of externally supplied components and giving clients a hands on experience of design.

We have a selection of FDM 3D printers that are great for quickly creating accurate parts for testing the fitment, form and styling of designs. We alos have a SLA resin printer that is great for creating parts with a higher level of detal and finer surface finish. The parts from this printer are ideal for testing fine fitment between mechanical parts and creating parts that are ready for painting with minimal surface finishing.

Between the range of printers and materials on site at Procreate we are able to efficiently make parts for appearance and functional testing.

Product Testing

We strongly recommend developing a test plan at the very start of the design process. It is an integral part of our design process and ensures that your product will deliver on what it is designed to do.

Testing can cover an enormous range of things. Some of the more popular include:

Weather resistance/water-proofing

Dust resistance

HALT and HASS testing (life testing of products) that helps to identify the reliability of the various elements of the design over the product’s expected life time

Vibration testing and analysis

Impact testing

Electronic compliance is also tested via third-party experts

We will work with you to gather information as to the kind of testing that will be appropriate for your product. Testing then occurs all the way through the product’s design and development - from the virtual CAD environment through prototyping and manufacture. As the product design process progresses, the tests get more specific and less tolerant of failure to ensure that the finished product is reliable, robust and fit for purpose.

Product Manufacture

There are many examples of product designs that have been 'found out' at the manufacturing stage because the design has not taken sufficient account of the manufacturing process. Our ability to combine design and engineering expertise under the same roof eliminates these issues.

Our design solutions take account of the engineering and manufacturing requirements to ensure that manufacturing can be as efficient as possible. Our product creation process is both more rigorous and faster - enabling you to move from concept to manufacture more efficiently and with a high level of product reliability built in to the design.

Production Management

Procreate offers a service to manage production runs for clients. Our knowledge of manufacturing processes makes this a logical extension for many companies who do not have this expertise in house. We typically get directly involved in managing low-volume, high-value manufacture runs, and can facilitate the manufacture of high-volume production through our network of suppliers.

Procreate’s familiarity with the design makes it logical for us to continue managing the product delivery. This considerably de-risks the product manufacture for our client.

Procreate has strong working relationships with a wide variety of suppliers locally and internationally. This gives us access to an enviable range of manufacturing options and allows us to identify the most efficient and cost-effective means of supplying raw materials and physical manufacture of the products we design.

Tooling

Procreate can organise tooling for the components it designs and has a range of talented suppliers in NZ and overseas. Tooling is very much an ‘unseen art’ and is an absolutely critical part of most modern product manufacture. Commonly Procreate gets involved with projects requiring tooling for plastic injection modelling or thermo forming but we have suppliers who offer the full range of alternative manufacturing processes and materials as well.

Creating a ‘tool’ or mould is a highly expensive and customised process, so getting it right the first time is critical. At Procreate we start considering the tooling options and constraints right at the start of the design process. This high level of attention to detail then extends through to the prototyping stage where tooling requirements are fine tuned.

Our deep understanding of the engineering requirements of tooling and the impact that it has on the manufacturing process has been part of Procreate’s success story. It is an aspect of manufacturing that most people never get to see – but it can have an enormous impact on every aspect of the product’s look and feel, including its ultimate cost.